Our Equipment

State of the art printing, cutting, and finishing equipment

Printing, Cutting, & Finishing Equipment

Leverage Our Cutting-Edge Technology

Here at Digital Impact, we combine our industry leading knowledge and expertise with advanced, state-of-the-art equipment to deliver results that exceed our clients expectations. Whether it be our high-tech digital printers from Durst or either of our Die Cutters from Esko and Elitron, we possess the tools needed to bring your idea to life.

Looking for a Quote?

Durst Delta WT 250 Large Format Water Based Digital Printer

- Print Resolution of up to 1200 dpi with 6 Colors – CMYKcm

- Durst Water Technology Inks are completely free of Hazardous Labeling

- Durst Water Technology provides odorless, litho quality, environmentally friendly print reproduction on corrugated board.

Durst Rho 900 Large Format UV Based Digital Printer

- Print Resolution of up to 900 dpi with 7 Colors – CMYKcm and White

- Prints on all substrates; corrugated, plastics, roll to roll material.

Ready to Get Started?

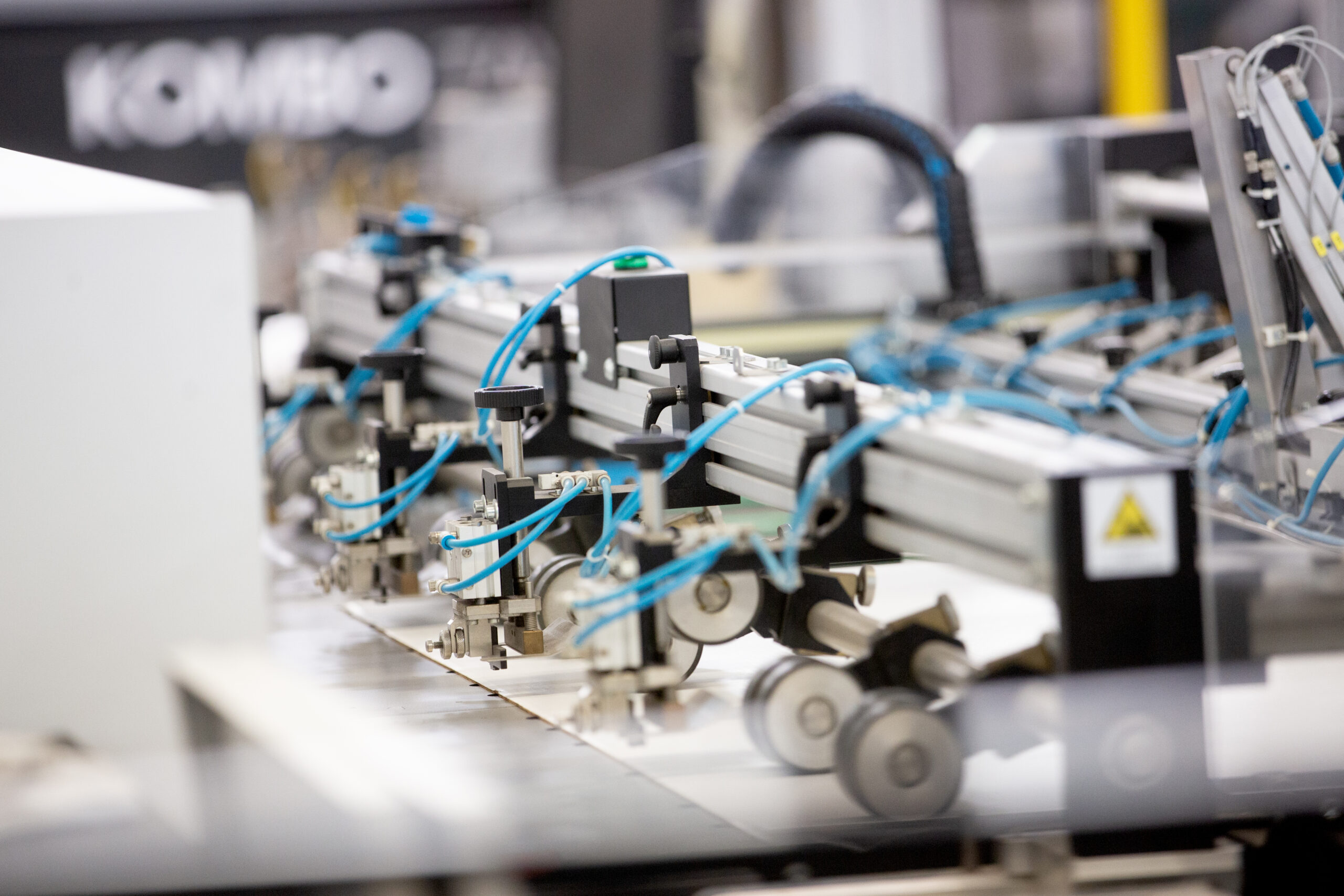

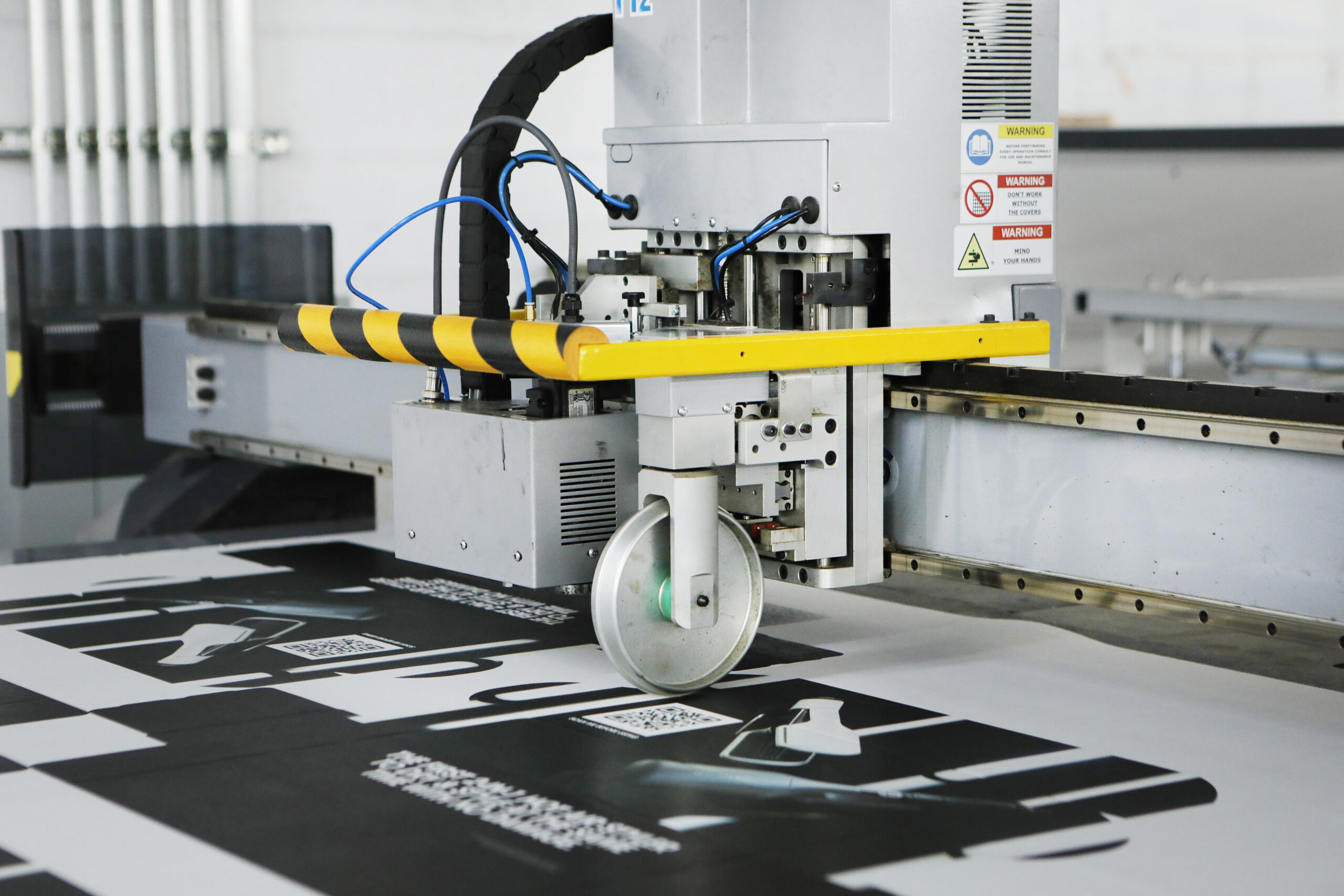

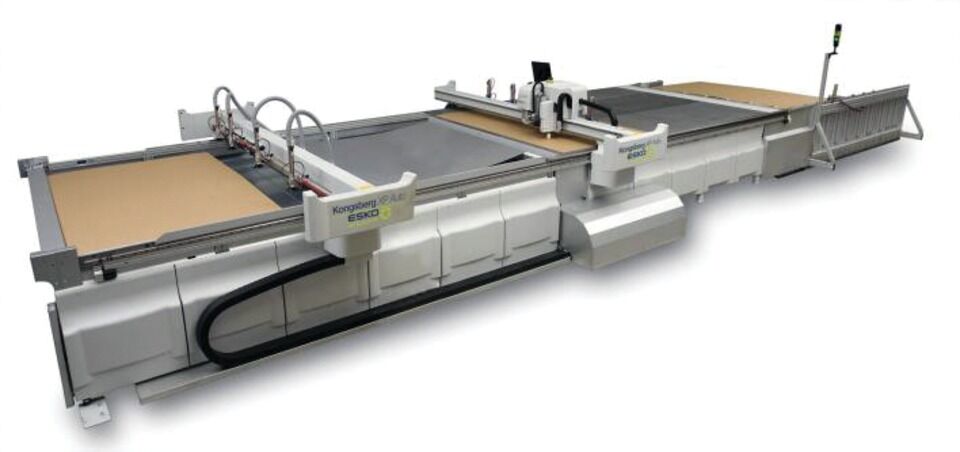

Digital Finishing Esko Kongsberg Die Cutters

Digital Impact utilizes 2 Esko Konsberg Cutting tables. 1 XP 44 Auto, 1 DCM tables. All of the tables have automatic load and unload from the table providing a fast through put of material for scoring and cutting. A camera system allows for accurate print to cut registration saving time and bringing down production costs. This method allows for jobs to be put through without any tooling costs as no physical dies are required for any job. The XP Auto has routing capabilities so that it can handle rigid materials such as acrylic, Styrene, Di-Bond, Wood and thicker materials.

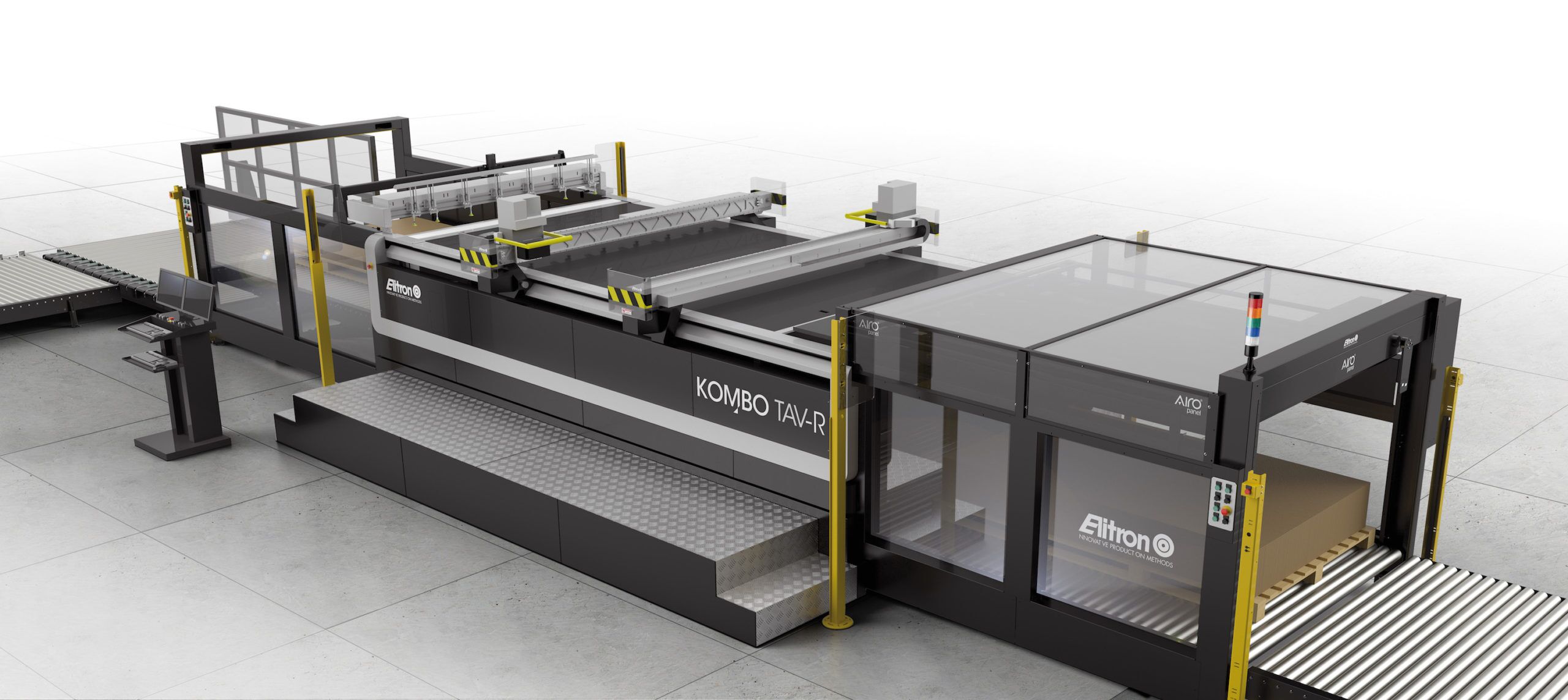

Elitron Kombo TAV Die Cutters

To continue our investment in advanced cutting technology, we are currently using 2 Elitron Kombo TAV-R Die Cutters. These are the only plotters with two independent cutting heads able to cut at speeds of up to 102 mt/min. The Kombo TAV-R flexible dieless finishing system cuts production times and reduces costs whilst offering maximum versatility for both short and complex production runs. This further automates our entire production process, reduces costs, and delivers a non-stop workflow.