Retail Food Displays & Packaging

High-quality Paperboard Solutions for Retail Food Packaging & Displays

Food & Beverage Displays & Packaging Manufacturer in Philadelphia, PA

Enhance Your Retail Food Packaging

At Digital Impact, we specialize in delivering personalized Food & Beverage packaging and display solutions. Our dedication to cutting-edge design and sustainable principles ensures that we elevate brands through visually captivating and eco-friendly packaging, enhancing product visibility and fostering meaningful consumer connections.

Ready to Get Started?

Custom Food Packaging Manufacturer

Helping You Stand Out On Shelves

Experience the power of custom-designed food packaging and displays that command attention on retail shelves. Our tailored solutions are crafted to not only showcase your products but also entice consumers with visually compelling designs that reflect your brand’s uniqueness, ultimately setting your offerings apart in the competitive market.

Your Go-To Team for Food Packaging

Primary & Secondary Food Packaging

Primary Food Packaging made from suitable corrugated cardboard or carboard material surrounds the food directly. Here too, the outside of the packaging is printed without any direct contact between the printed surface and the food.

- SQTS-Certified

- GMP Production

- Swiss Ordiance

- Nestlé Compliant

- EuPIA

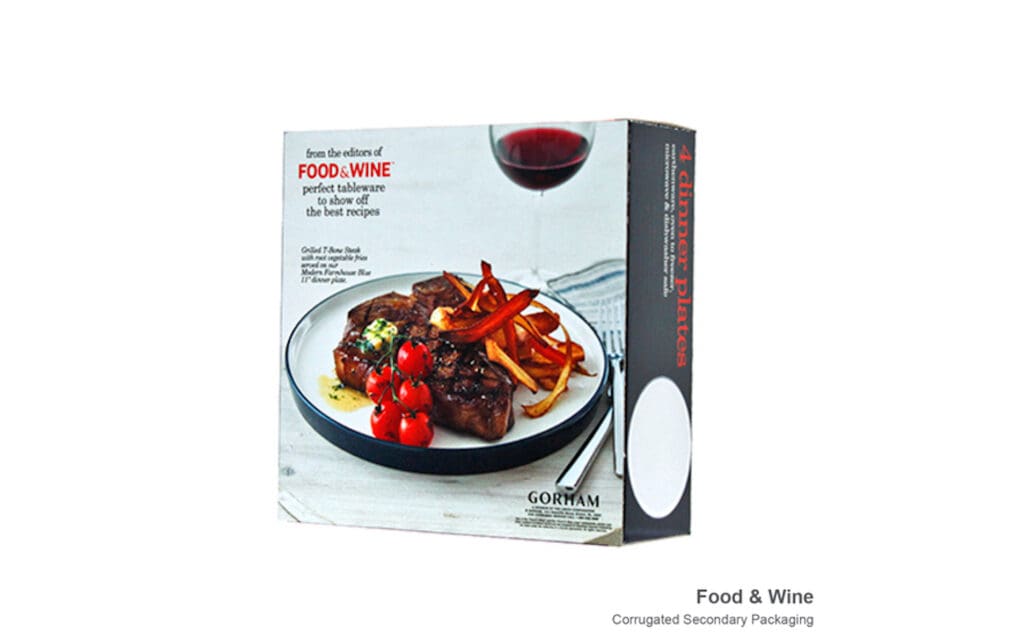

Secondary Food Packaging made from suitable corrugated cardboard or cardboard material contains primary packaging with sufficient barrier properties, such as cans, jars, or pouches. The outside of the packaging or display is printed without direct contact with the food.

- SQTS-Certified

The Advantage of Using Our Durst Press

Our Durst Press uses water-based and odorless WT inks for printing. These inks do not have any labels, do not contain hazardous components, and comply with the highest health and safety standards. The print results provide off-set quality in look and feel, providing added value to our clients.

Both sets of ink are based on the same formula, although their production method differs. Since production according to the GMP standard is defined, among other things, as a fundamental legal requirement for the printing of Primary Food Packaging, Durst needed to use the associated GMP production routines for Durst Water Technology Food Inks that now not only comply with just the Swiss ordinance, but also with the relevant EuPIA guidelines and the Nestlé Guidance Note on Packaging Inks.

Our Press is not only an environmentally friendly alter- native for the production of low-odor POP/POS applications, displays and packaging for in-store applications. Thanks to the continuously increasing demand for these products, it is a secure future investment.

Our Durst Press enables us at Digital Impact to continue using water-based inks in our largest market, the food and beverage industry. This is crucial for our business. With our investment in Durst Water Technology, we will make our expertise in packaging development and design accessible to a new, specialize target group with smaller print runs, as well as offer new markets for our clients.

- Litho-Quality

- GMP-Compliant WT Inks

- Digital Workflow

- Odorless Inks

Have a Question? We Have an Answer.

Frequently Asked Questions

Elevate your retail food products with our expertly crafted food packaging solutions designed to enhance shelf appeal, communicate product excellence, and drive consumer engagement.

How can your packaging solutions contribute to increased sales and brand recognition in the retail food market?

Our packaging solutions play a pivotal role in driving sales and enhancing brand recognition in the retail food market. By creating visually appealing and informative designs, we help your products stand out on crowded shelves, attracting the attention of consumers and encouraging purchase decisions. Our strategic approach to packaging aims to create a lasting impression, fostering brand loyalty and increasing repeat purchases as customers identify and connect with your brand through its distinct packaging.

What materials do you use for your food packaging, and are they sustainable?

We offer a variety of materials for food packaging, catering to both functionality and sustainability. Our options include recyclable, biodegradable, and compostable materials, promoting eco-friendly practices in packaging solutions. We are committed to providing sustainable choices that align with your brand’s environmental objectives without compromising on the quality or durability of the packaging.

Can you accommodate custom branding and design requests for our food products?

Absolutely. We specialize in creating custom branding and design solutions tailored to your food products. Our team collaborates closely with clients to understand their brand ethos, values, and target market. We integrate these insights into our designs to create distinctive packaging that reflect your brand identity, ensuring consistency and a strong brand presence across all your products.

Food & Beverage Packaging Manufacturer

Innovative Packaging and Display Solutions for the Retail Food Industry.