We installed our second Elitron Kombo TAV Die Cutter in September 2022. After installing our first, we saw a significant reduction in production times and costs. So much so that we have invested in a second machine to uphold our commitment to providing best in class services.

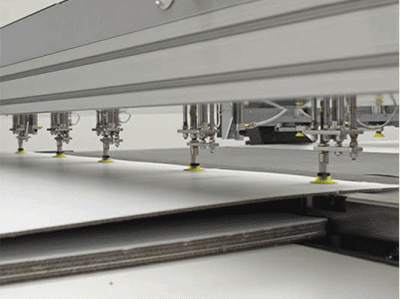

The sheets positioned onto the pre-loading area are read from below, using Seeker System, the dual camera vision system patented by Elitron, which detects the reference points for a perfect synchronization of the cutting path with the printing. Seeker System also identifies the barcodes/qr-code for the automatic loading of the relevant cutting files.

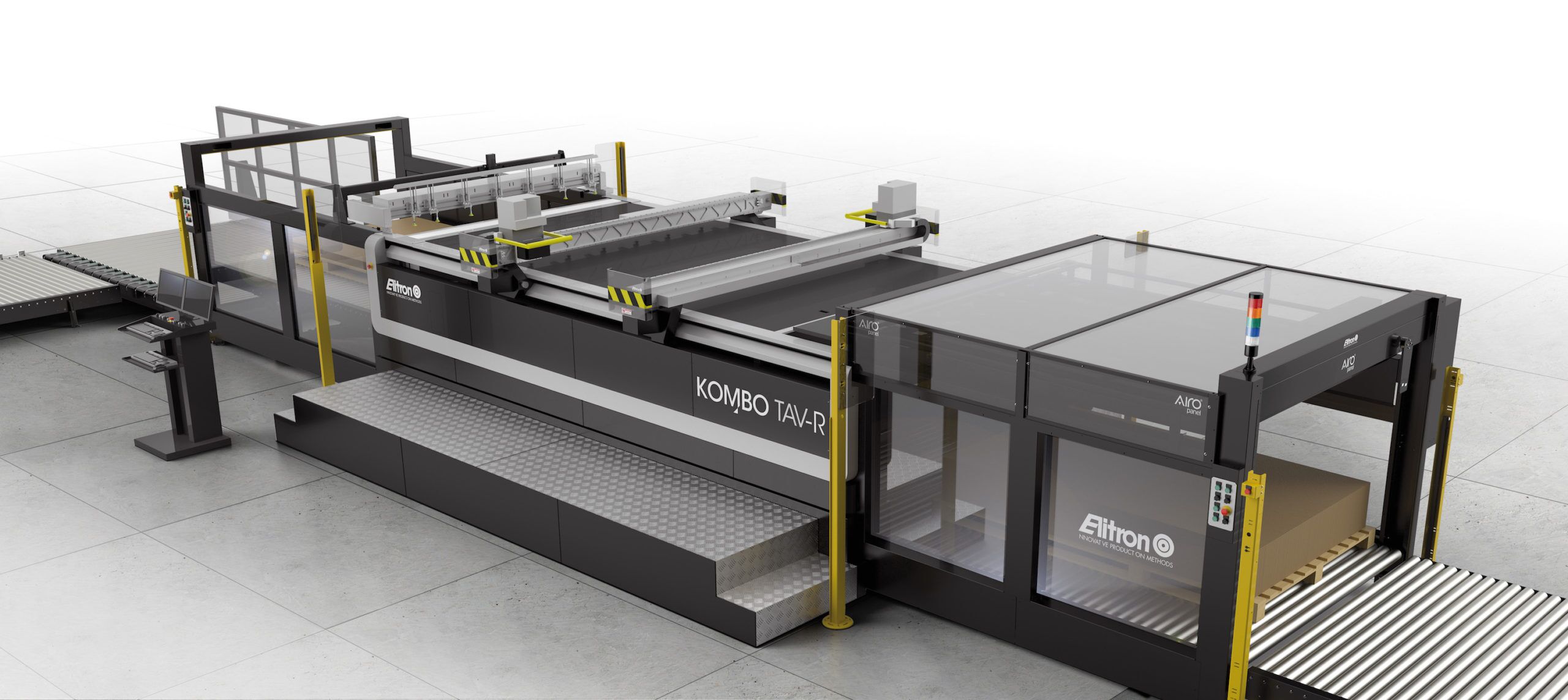

Wide flexibility through the multi-sheet loading management and the selection of the feeding modes: by lifting table, by carriage, up to the roller conveyor automatic feeding. Possibility to load up to 120 cm of material.

High cutting quality for the absence of unsightly nicks, no longer needed, and easy scraps removal. The whole working area, whether loaded in single or multi-sheet, is fully unloaded in one go through Airo Panel, an exclusive Elitron’s Patent, powerful panel that sucks all the processed sheets at once, carries them to the unloading area, stacking them onto a pallet.

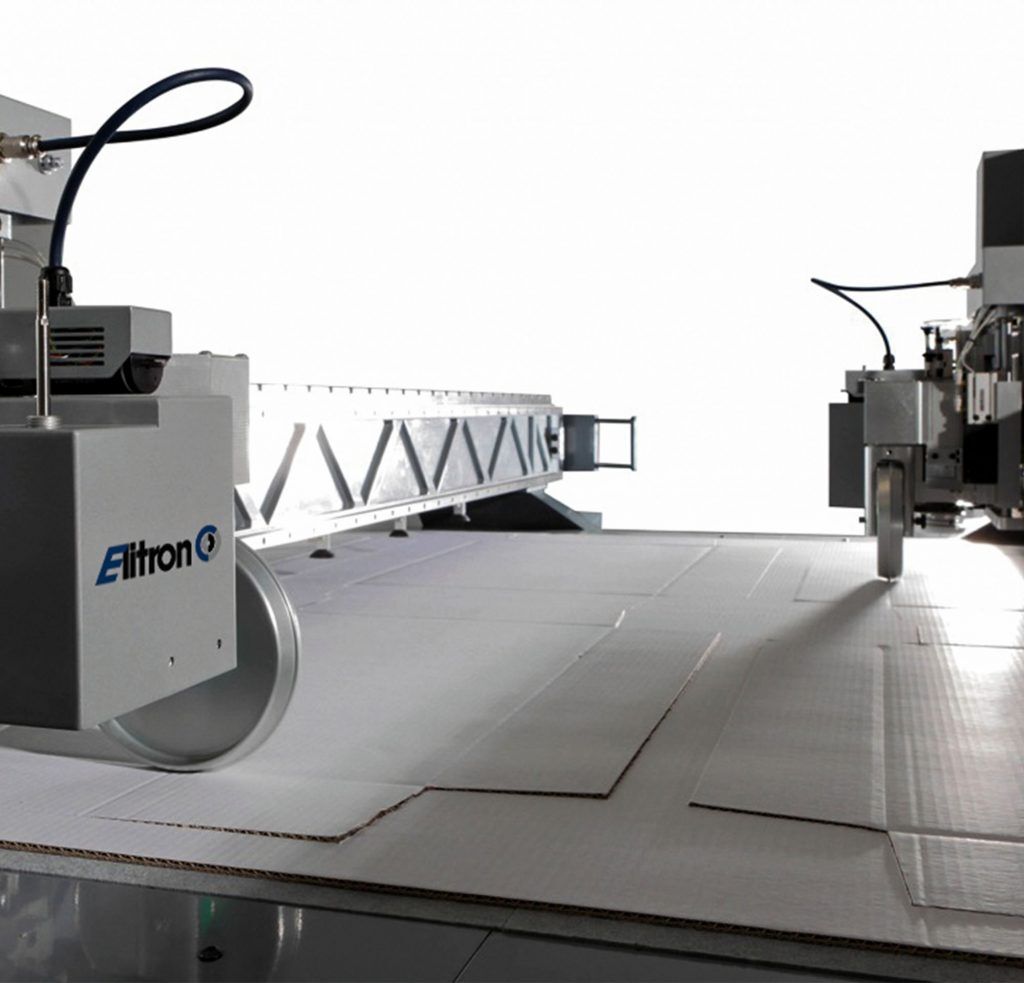

Maximum productivity thanks to the two independent multi-tool cutting heads operating simultaneously on the whole cutting area. Elitron’s TwinCut software calibrates and assigns the workload to each of the cutting heads, optimizing the overall time. Cutting and creasing of materials up to 20 mm thick.

The pre-loading system reduces the downtimes optimizing the material loading, preparing the reference points detection and positioning the material in a stand-by zone, all while the two cutting heads work.

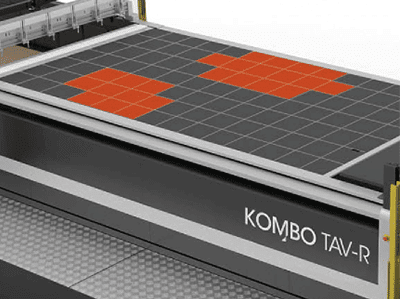

Cutting area up to 3200 x 2200 mm with suction surface made up of 24/32 sectors for the perfect adherence of the materials, even the most critical ones.

Installing our second Elitron Kombo TAV-R Die Cutter signals our continued investment in advanced cutting technology. These are the only plotters with two independent cutting heads able to cut at speeds of up to 102 mt/min. The Kombo TAV-R flexible dieless finishing system cuts production times and reduces costs whilst offering maximum versatility for both short and complex production runs. This further automates our entire production process, reduces costs, and delivers a non-stop workflow.

This installation of our second Elitron Kombo TAV-R Die Cutter will allow us to strengthen our position as a leader in our industry. We look forward to the cost savings and enhanced production capabilities this will provide us and our clients. If you have any questions or would like to get started today, give us a call or fill out our contact form. We are eager to get the opportunity to work together on something great!

Feel before you buy. Fill out the form below and a member of our team will reach out to you shortly to discuss the needs and logistics of your project along with going over the quote in detail!